For the last 20 years, we’ve been manufacturing a variety of copper-brass core styles in-house at our Winnipeg, Manitoba shop. Our copper-brass manufacturing department has expanded and changed over the years, and we very are proud of the evolution. So let us walk you through our manufacturing processes that result in manufacturing a proven, high quality product delivered to our customers without any supply chain delays.

Our Copper-Brass Manufacturing Department

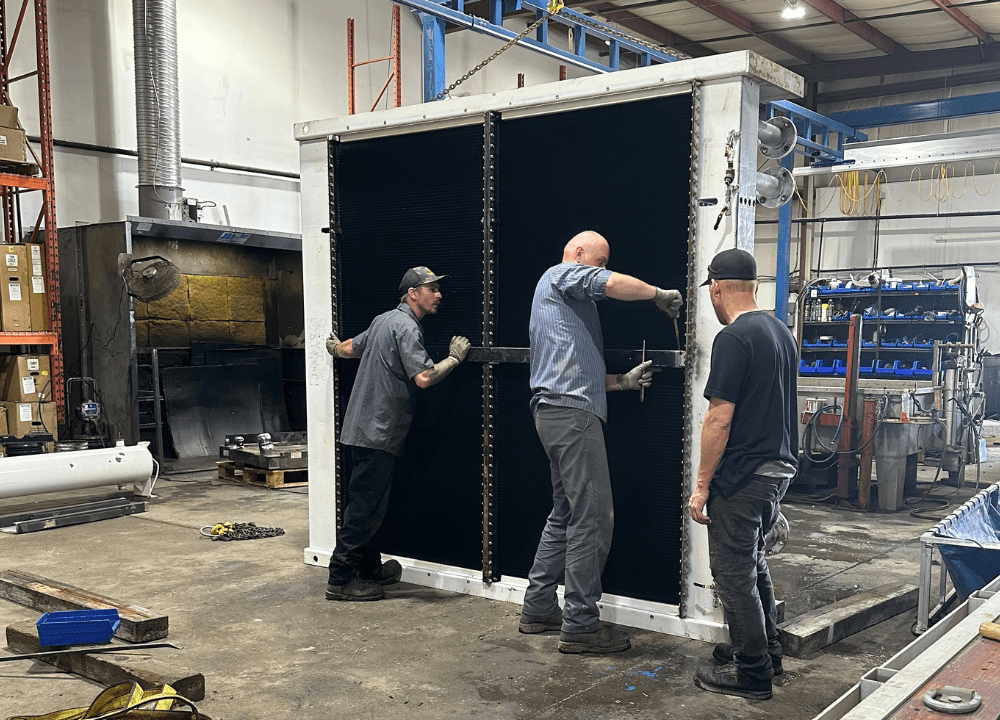

Our copper-brass manufacturing department is located in our Winnipeg, Manitoba Canada shop at 2008 Logan Avenue. We have a highly skilled team of machinists and shop technicians working full time in this department.

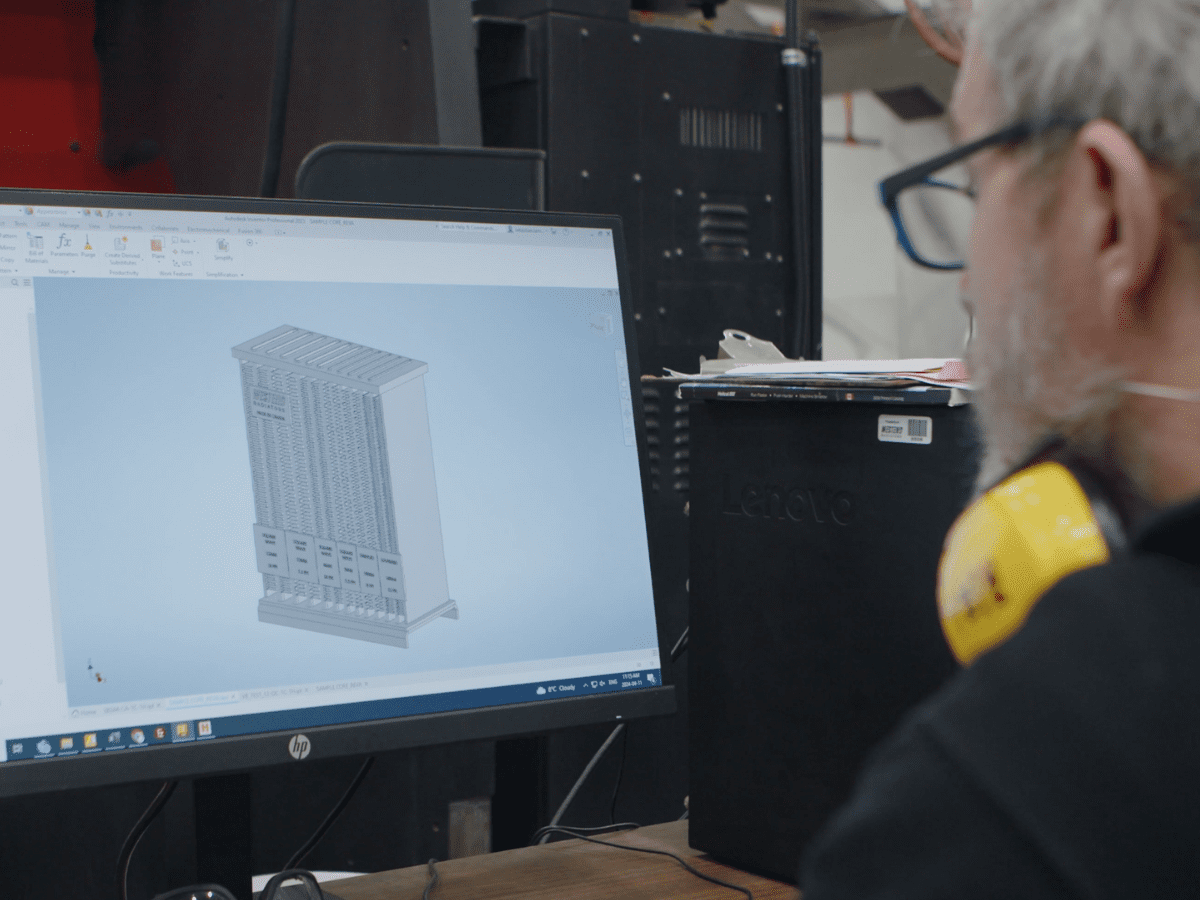

Our copper-brass manufacturing equipment is state-of-the-art, such as our CNC press that allows us to manufacture accurate and precise brass radiator headers.

Additionally, we manufacture a range of core styles, radiator fins and tubes.

We manufacture copper-brass cores as well as offer recores for a full range of heavy-duty OEMs in industries such as;

- Transportation

- Agriculture

- Mining

- Construction

- Oil & Gas

- Power Generation

- Forestry

Our team can also manufacture custom fins from copper, brass or steel to properly fit your machine’s application.

Copper-Brass Heavy Duty Heat Exchangers

We manufacture complete custom copper-brass radiators for industrial and commercial applications. Our team can manufacture a custom core built to your exact specifications as well as recore your existing radiator.

We manufacture the following copper-brass heavy duty replacement parts for :

- Bolt-on radiators

- Brass headers

- Custom fibre flex gaskets

- Heavy-duty gaskets for bolt-on rads

You can learn more about our copper-brass heat exchangers and what sets us apart here.

Copper-Brass Radiator Suppliers

Did you know, we carry the largest inventory of aftermarket rads and cores in Western Canada? And while we’re located in the middle of the Canadian Prairies, we can quickly ship parts across North America and beyond! We’ll work with your shipping supplier to offer you the best freight rate.

You can contact our Parts & Service team toll-free at 1-877-RAD-CORE (723-2673) for more information and to see if we have the part number you’re looking for.

If you prefer shopping for parts online, we invite you to browse our inventory here on our e-commerce website.

Here you can shop for a large selection of aftermarket copper-brass rads, cores, CACs (charge air coolers) and A/C condensers for the following OEMs:

- Ford/Sterling

- Freightliner

- Genset

- International

- John Deere

- Kenworth

- Mack/Volvo

- Peterbilt

- Western Star

Do keep in mind, that while we are updating our online shop regularly, it does not yet display our full inventory. So if there’s a part you’re looking for that you don’t see online, simply reach out to our team and they’ll be happy to help.

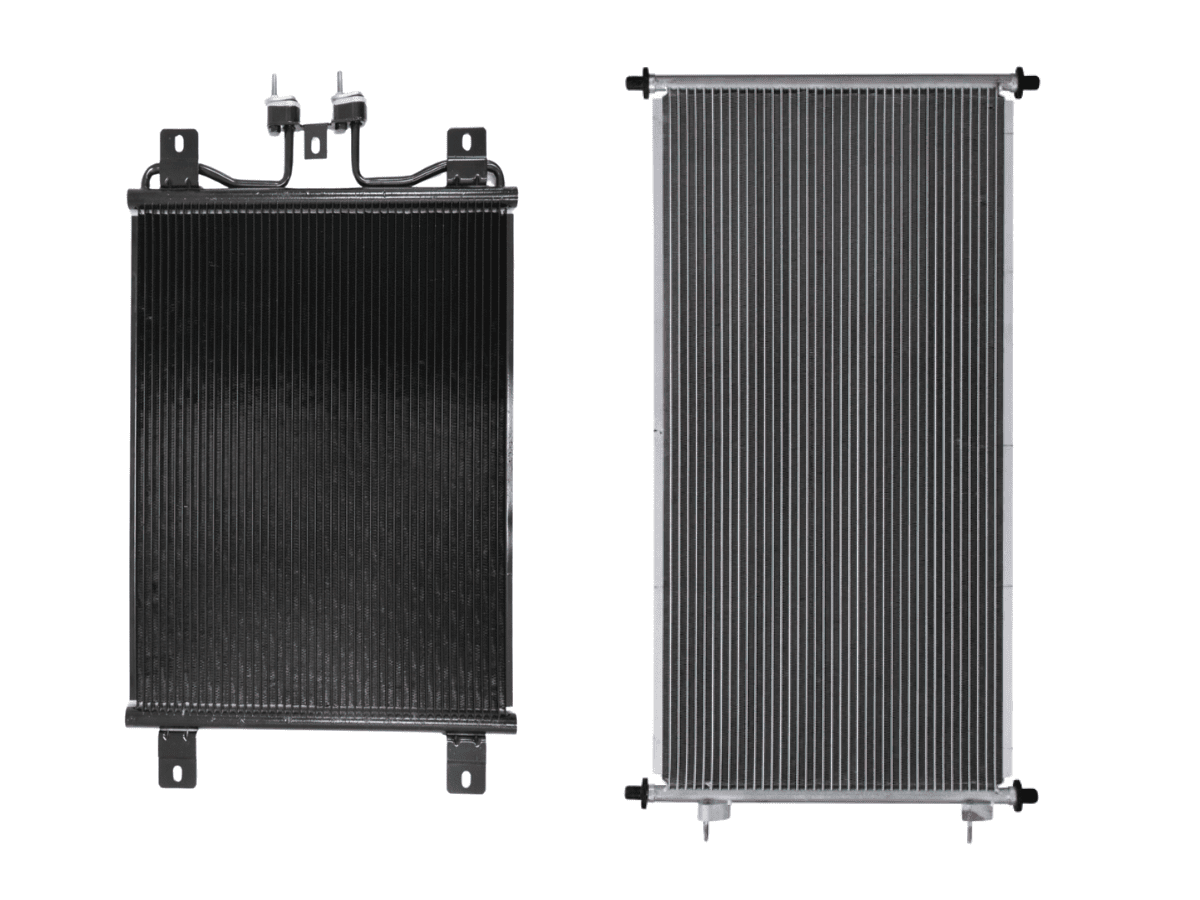

Copper-Brass Radiator vs. Aluminum Radiator

Over the last few years, we’ve also been building our in-house aluminum core manufacturing department. And so we often get asked by our customers “what’s better, a copper-brass radiator or an aluminum radiator?”

The answer is it depends on your machine’s needs and the environment you’re using it in. So here’s some of the benefits of copper-brass rads vs. aluminum rads.

The Benefits of Copper-Brass Radiators:

- Can last up to 6,000 hours without failure

- It’s a trusted material

- It’s an excellent heat conductor

- It’s extremely durable and easy-to-repair

The Benefits of Aluminum Radiators:

- Strong thermal properties, allowing it to conduct heat efficiently

- Aluminum is a 100% recyclable material

- Can withstand extreme working conditions

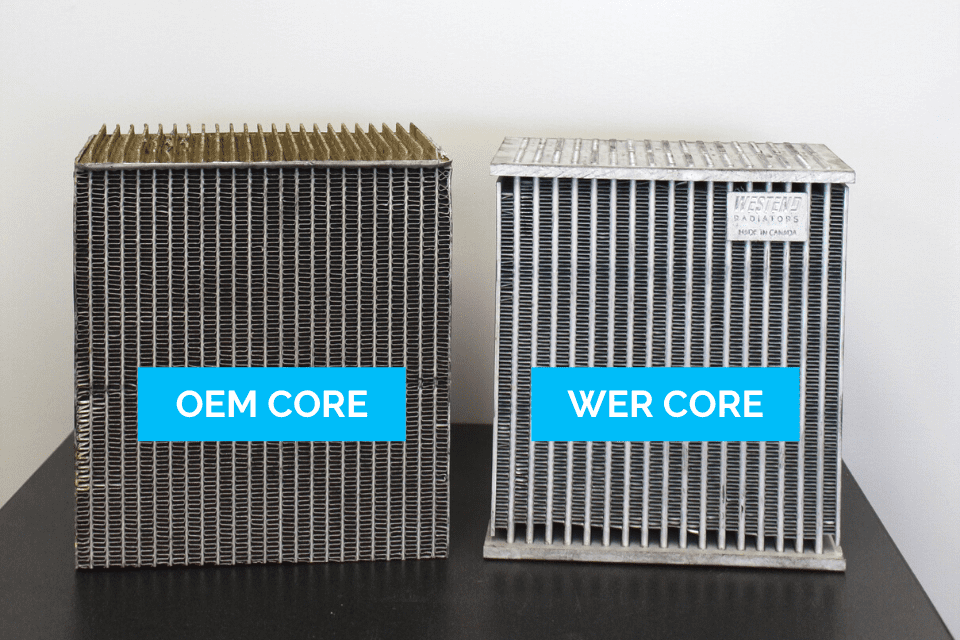

- The aluminum tubes West End Rad manufactures are larger than the OEM, which can accommodate heavy-duty demands better

You can learn more about our aluminum heat exchangers here.

Why Choose West End Radiators

What sets us apart from other copper-brass manufacturers is that we prioritize our customers’ needs and know how important it is to keep down time to a minimum. We want to get your machine back up and running quickly!

Further to that, we believe our copper-brass cores are superior to our competitors because they’re made in Canada and manufactured 100% in-house.

From scientists, engineers and machinists, to specialized mechanics; our diverse team is made up of talented individuals from around the world who love what they do.

Find The Copper-Brass Heat Exchanger You Need

Contact our team to see if we have the part number you need or if we can custom manufacture the replacement part for your machine.

We’re open Monday-Friday 9am CT-5pm CT.

Remember, you can always browse our parts online at shopwestendrad.ca and contact us for pricing when you find what you’re looking for.