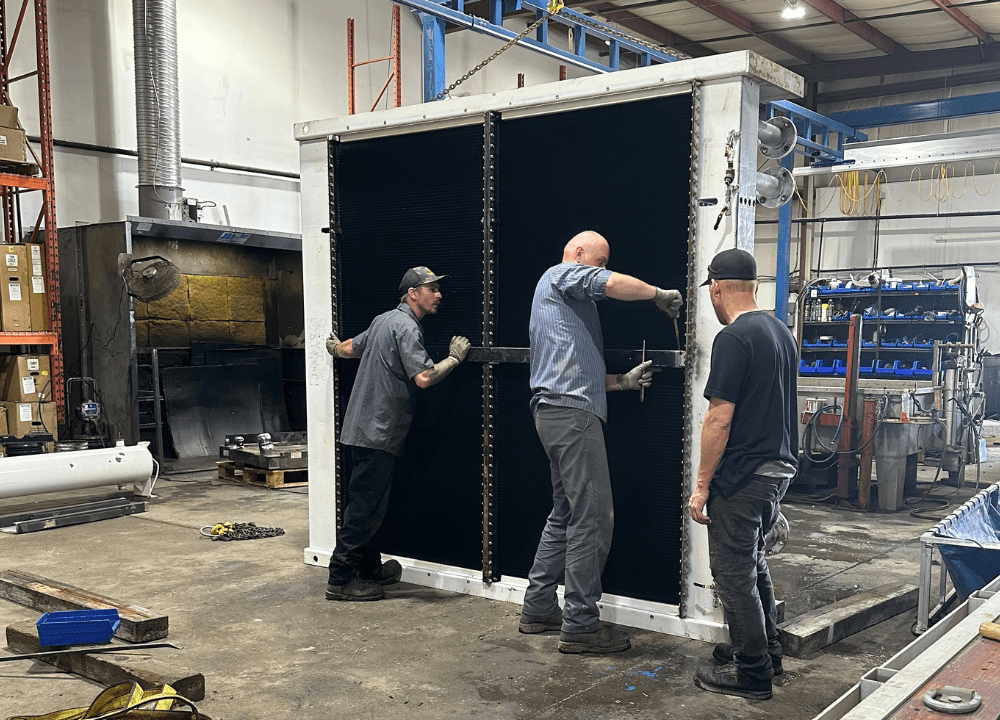

When it comes to a Mesabi rad repair, it typically becomes an “all hands on deck” type of job in our shop. These are massive rads that require careful attention and care. We’re proud to have designed our shop to specially be able to maneuver rads of this size while providing a high quality and long-lasting repair job.

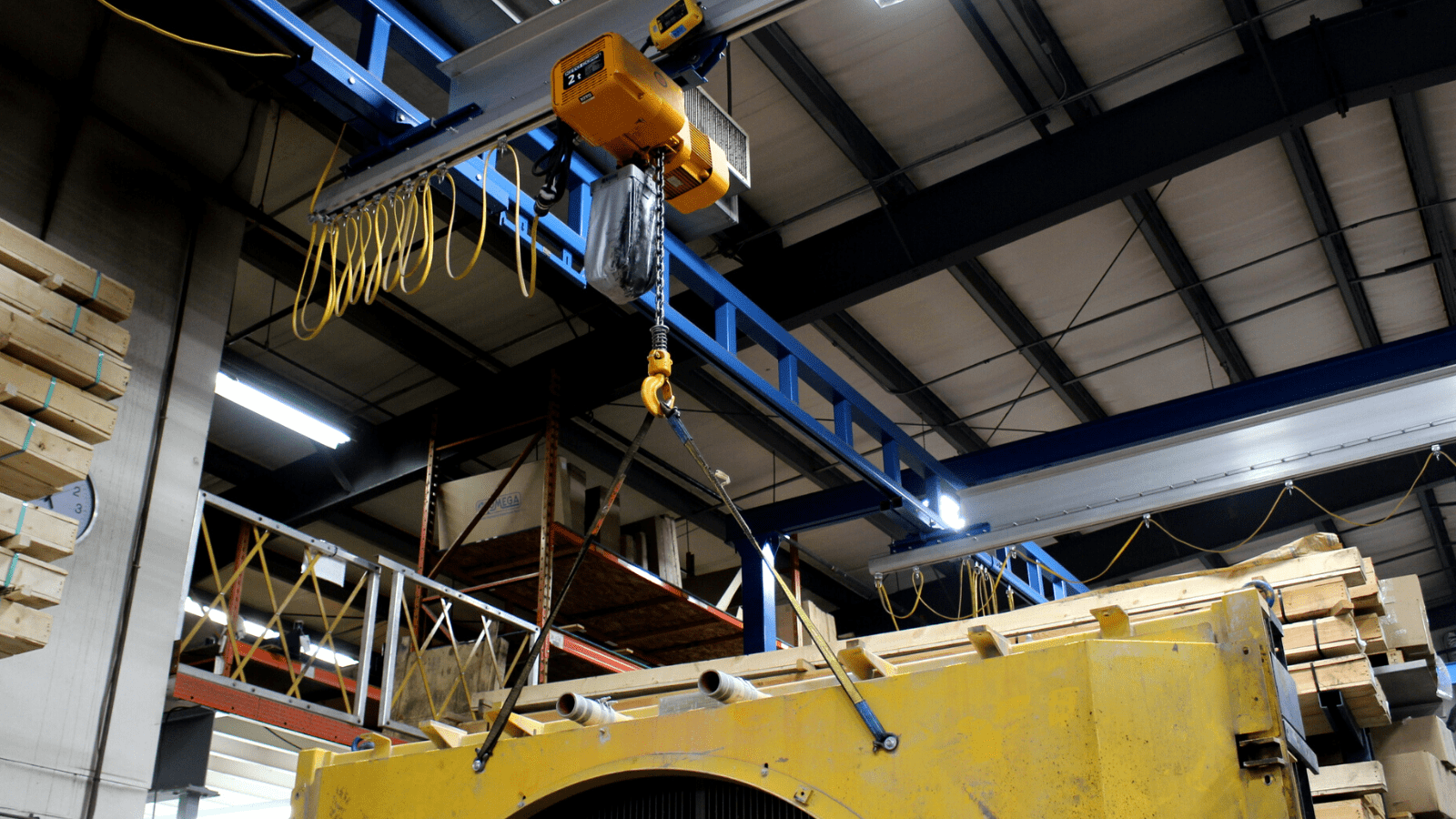

This was the case for a recent Mesabi radiator we did for an out-of-province Canadian mine. This is a job we are well prepared for at West End Radiators and have specialized, heavy-duty cranes that allow us to handle large radiators safely and efficiently.

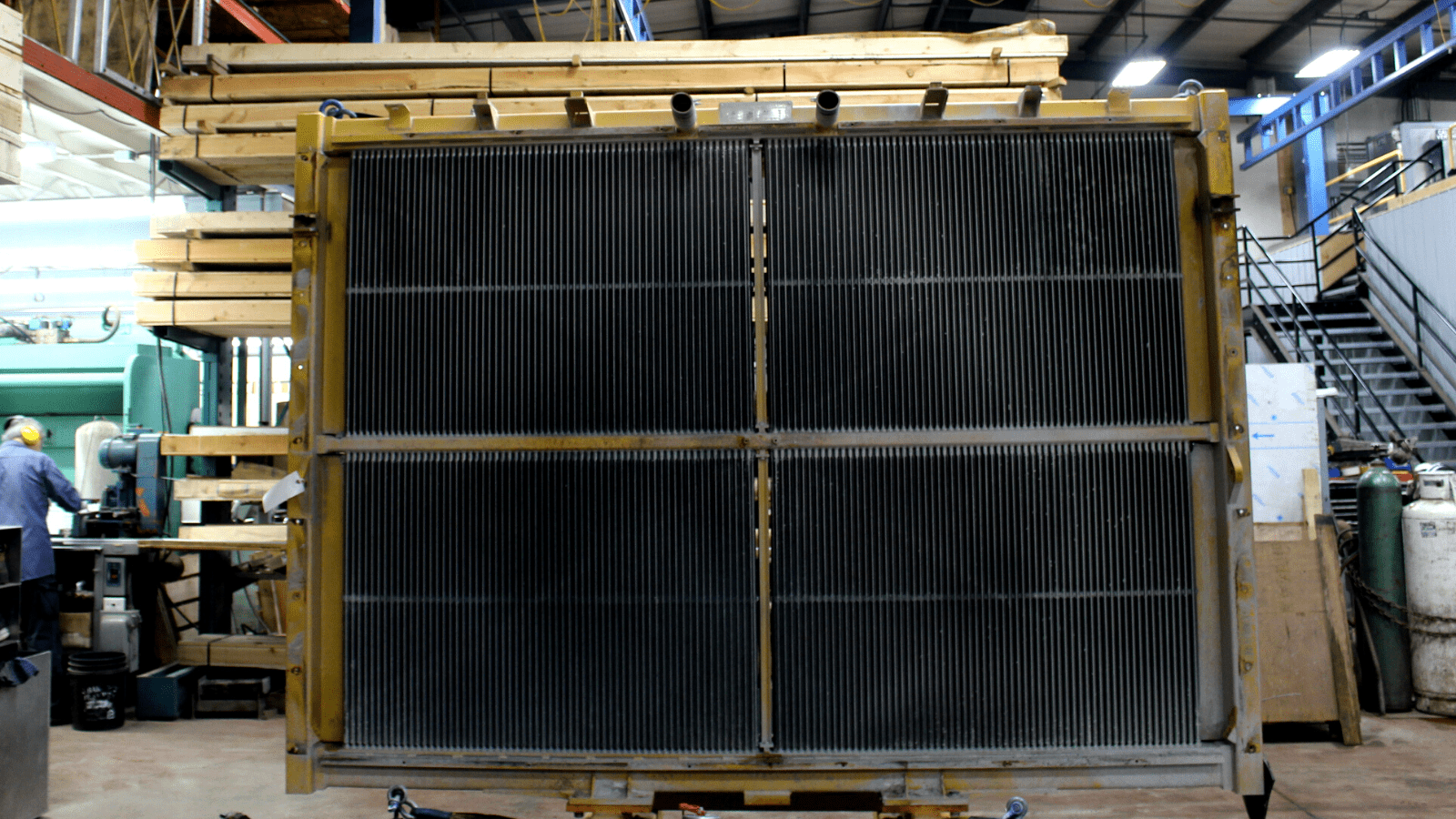

So here’s a look at the Mesabi radiator rebuild we did to help our client’s mining haul truck be able to withstand the extreme conditions it works in.

West End Radiators Case Study – Mesabi Rad Repair

The Job:

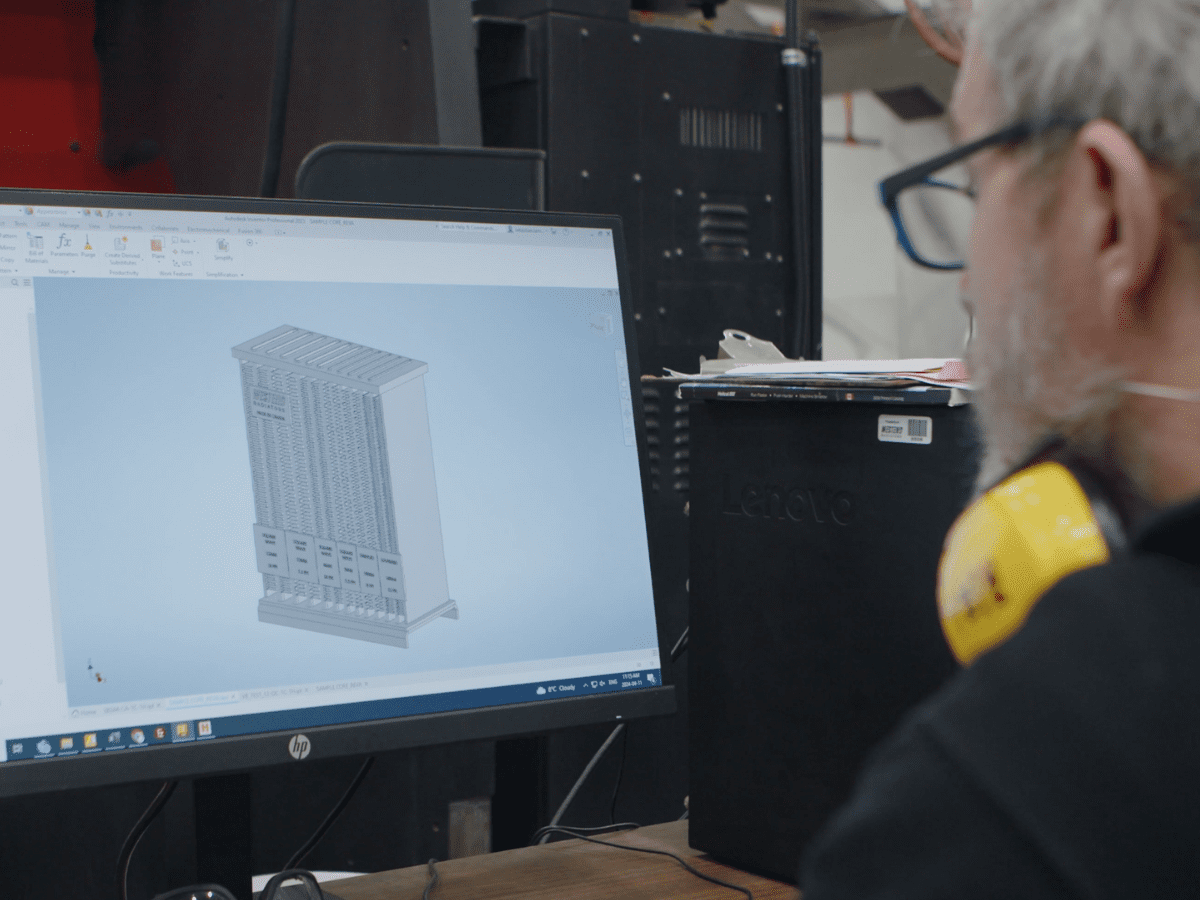

The client brought us this Mesabi radiator from a mining haul truck that required a complete rebuild with new tubes and seals.

Problem:

This radiator had reached the end of its service life. The haul truck in which the radiator came out of was due for a complete rebuild, which happens approximately every two years, if it’s being used 24/7 and in extreme conditions.

As a preventative measure, our Shop Technicians identified that the radiator needed to be completely rebuilt to withstand the next extreme tour of duty. Having a radiator fail early in its working life means thousands of dollars of lost revenue. This is something undoubtedly we wanted to ensure our client didn’t have to endure!

Solution:

Our team of shop technicians and mechanics started by using our significantly large overhead cranes to remove the huge radiator off the flat deck trailer it arrived on. Our shop is large enough to allow the entire truck and trailer to park safely inside for this lift.

Once the radiator is in place on our shop floor, our team can then begin the inspection, testing and rebuild process.

We have two of these cranes in our Winnipeg shop.

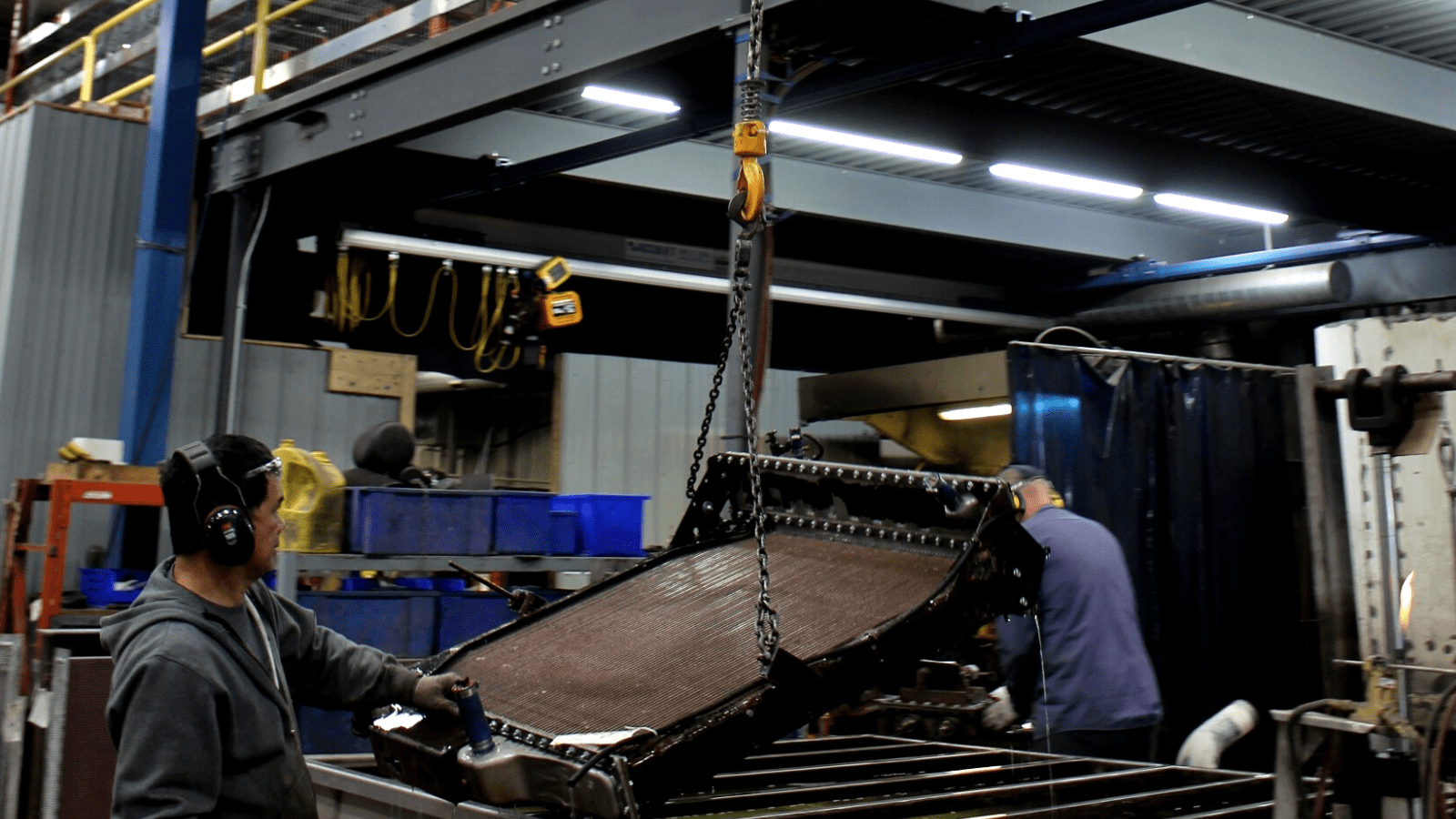

Each crane allows us to lift parts up to 4,000 pounds. This sets our shop apart as it allows us to easily access the rad from all angles, remove each individual section and maneuver them safely through the shop.

We then removed every tube and seal from each of the cooling frames. The frame was then flushed, cleaned and prepped for installation of new seals and tubes.

Once this was completed, the individual frames were pressure tested to ensure there were no leaks.

Then, the entire radiator is reassembled and painted with a fresh coat of paint. Then we put the shroud back on so it’s ready to be shipped back to the client.

And there you have it!

That’s a look at the difference it makes to have your Mesabi rad repaired with West End Radiators. Our heavy-duty overhead cranes and specialized shop technicians ensure the job is done safely and efficiently.

Do your mining rads need servicing?

We’d love to help! You can contact our team directly by phone and tell us more about your rad. We’ll get you in for servicing within the same week.

Or, complete the form below and someone from our sales team will call you with an estimate within 24 hours or 1 business day.