Harvest season is right around the corner for farmers across Western Canada. Whether you are cutting hay, harvesting corn or making your way through a variety of grain crops — we want to help ensure your farm machines’ cooling systems stay in tip top shape.

We’ve asked our team of expert mechanics to share their servicing tips for combines, tractors, harvesters, balers and threshers. Our mechanics have experience working on a range of OEMs, including John Deer, Kubota, Ford, International, New-Holland, BobCat, Caterpillar, McCormick, Case, Challenger, Fendt, Ingersoll-Rand and JCB.

So, here are our three tips for maintaining your farm equipment this harvest!

3 Tips for Maintaining Your Farm Equipment’s Cooling Systems During Harvest

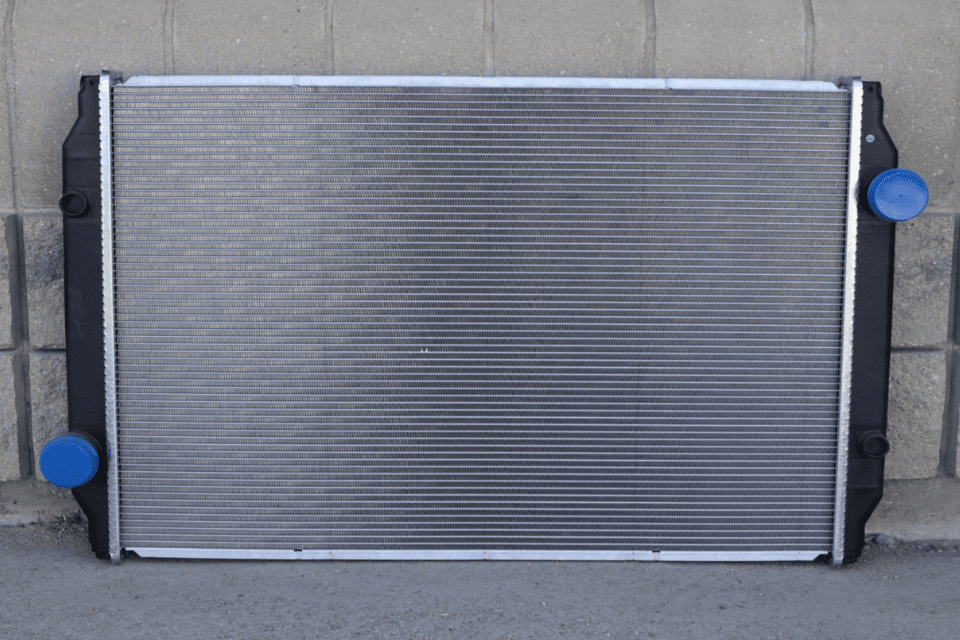

1. Closely examine your radiator for any debris clogs, cracks or leaks

During those long hours in the fields, it’s easy for coarse grain crops, dust and dirt to build up on your tractor’s radiator. Unfortunately, this build-up can increase the likelihood of your engine overheating.

Here are a few things that may be causing your farm rad to get plugged:

- Spacing between fins are clogged

- Rust buildup

- Age of rad and prolonged hours of use

So how can you fix the problem? You can blow out your radiator by blowing compressed air into the fan side (clean side) to the outside. It’s key you blow air this way to avoid embedding debris more into the core. We advise farmers use air rather than water for most machines otherwise debris will stick to the inner rad core, likely causing further issues down the line.

If you identify the fins are clogged or rusted out, we suggest you bring it in to us at West End Rad for additional testing.

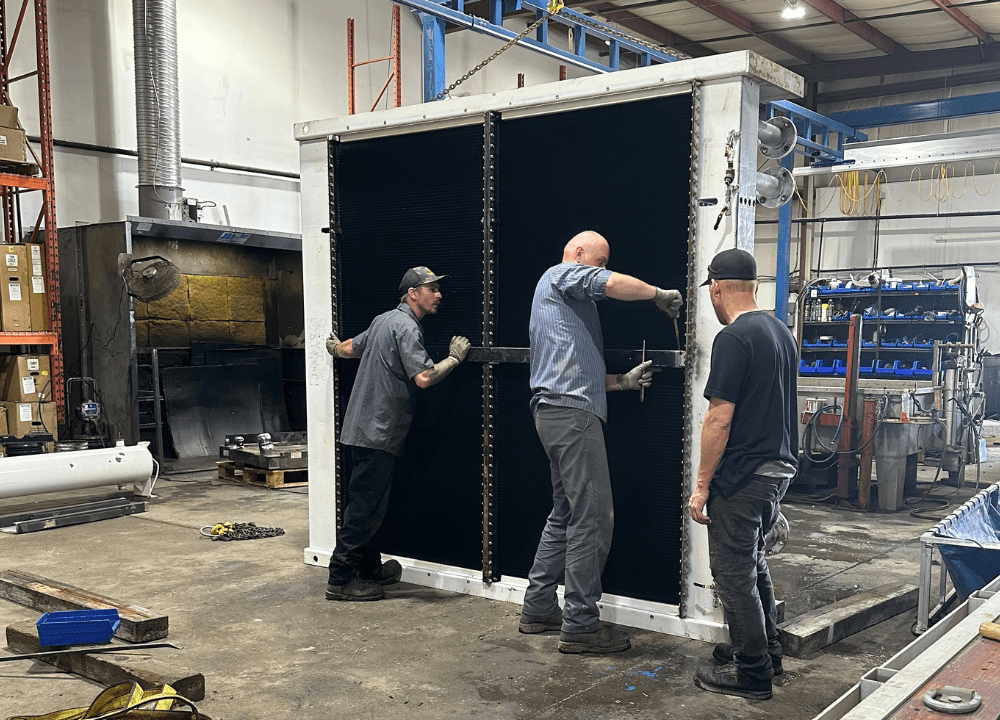

Our rigorous testing process allows us to identify exactly where the clog or hole is. Our process is expedited to ensure minimum down time for you. Once we’ve identified the issue, we determine the best type of materials for the repair.

We work with all-aluminum, copper/brass and plastic/aluminum radiators. Our heavy-duty, custom farm rads are stronger than the OEM and require less future maintenance, meaning more time in the field harvesting for you.

After performing a rad check, have you determined you’re in the market to replace your machine’s cooling system?

Here’s our three step check list of items to look out for when buying a new rad:

1. Choose a copper/brass or all aluminum rad. Radiators with plastic tanks are not as heavy duty and are prone to cracking. Our all metal rads are stronger than the OEM as we use heavy gauge metal. We also offer a one year manufacturing warranty. Learn more here!

2. Select a rad with up to 6 rows of tubes. We build all of our custom rads with up to six rows of tubes for superior cooling. This ensures the cooling system is as efficient as possible with the maximum amount of coolant moving through the core. A rad with more rows is especially important during harvest when your machines are running for long periods of time at slow speeds.

3. Choose a heavy duty reinforcement. There are a few reasons why your rad would require a recore, including fan damage, badly corroded tubes and fins, damaged tanks, and seam or header leaks. We offer all heavy duty reinforcements by using .090 gauge metal thickness.

Call our Sales team to learn more about our custom rads!

2. Check you A/C system to ensure no lines need replacing

Performing regular checks and maintenance to ensure your air-conditioning system is working at its best is key before harvest. We want you to be comfortable during those hot summer days! Air conditioning lines can get damaged from dirt build up, leaks, and loose or broken mounting hardware.

How do you know if there’s an issue with your cooling system? Here are 5 key signs:

- Not cooling

- Poor A/C performance

- Warm or slightly cool air emitted from unit

- Systems only working intermittently

- A/C or blower system being noisy

We carry a wide range of A/C aftermarket replacement parts with a 1 year warranty. Our team can also manufacture custom-made A/C lines for a range of farm equipment.

We are always committed to saving our farmers money, which is why we also offer repair services for A/C condensers and A/C evaporators. Often times, the cores of these units leak from being hit by debris, stones or overall wear and tear. Bring your A/C part into the shop and our expert technicians can evaluate and let you know what’s required.

Call our office to learn about all the A/C replacement parts we have in stock!

3. Check all your gaskets for any leaks, loose seals or poor fits

Your radiator’s gaskets are extremely important to keeping your entire cooling system operating efficiently. Gaskets act as a seal between your rad’s core and tanks. You want your farm rads gaskets to have a tight fit so no coolant leaks occur.

After prolonged use in dusty conditions, many OEM gaskets will become brittle and not seal properly. This is especially common for rubber gaskets. At West End Rad, we manufacture our aftermarket gaskets using a special heavy duty paper gasket material, which provides a more durable seal.

So how can you tell if your gasket is leaking or loose? Here are a two tell tale signs that your farm rad needs new gaskets:

- You’re loosing cooling system pressure

- You notice your engine temperature is rising

We have many type of farm gaskets in stock to have ready for you. However, custom gaskets can be manufactured in-house as needed.

Call us to get the right gasket for your machine!

And there you have it, our 3 tips for maintaining your farm equipment’s cooling systems during harvest.

Learn more about our full list of service here. You can also browse our full line of aftermarket inventory here.

Our Commitment to You:

- Efficient service for rush and emergency jobs

- Experts in heavy-duty industrial cooling

- 1-year warranty on all parts

- Customized repairs to fit your machine’s environment and needs