Forestry/Paper

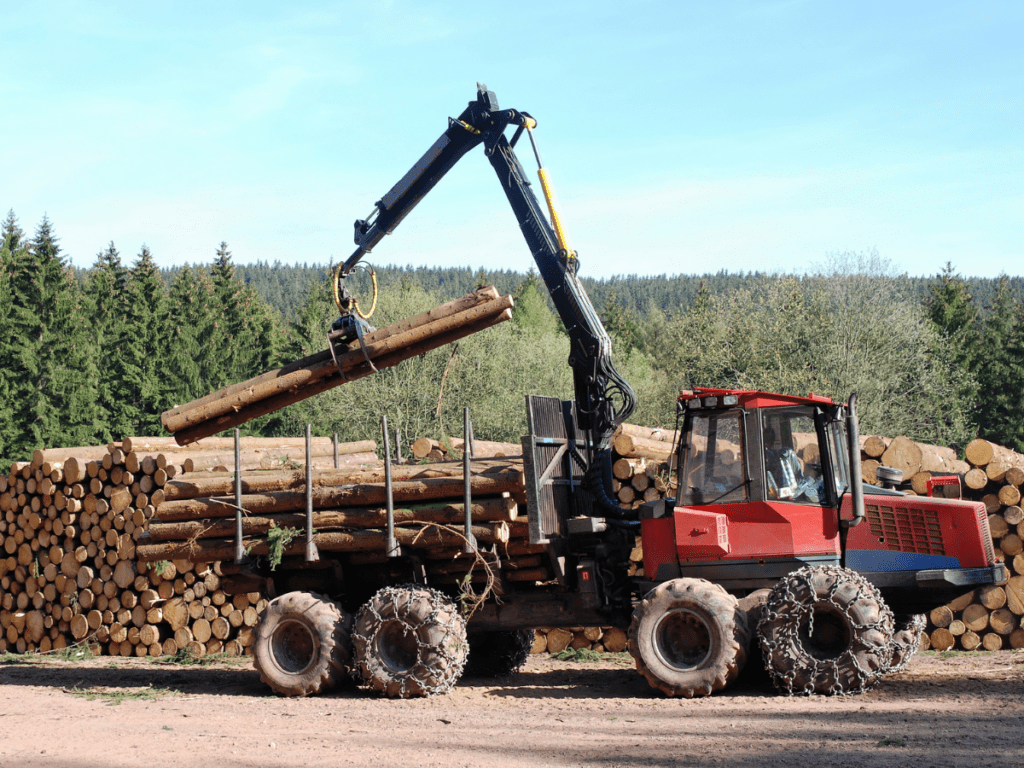

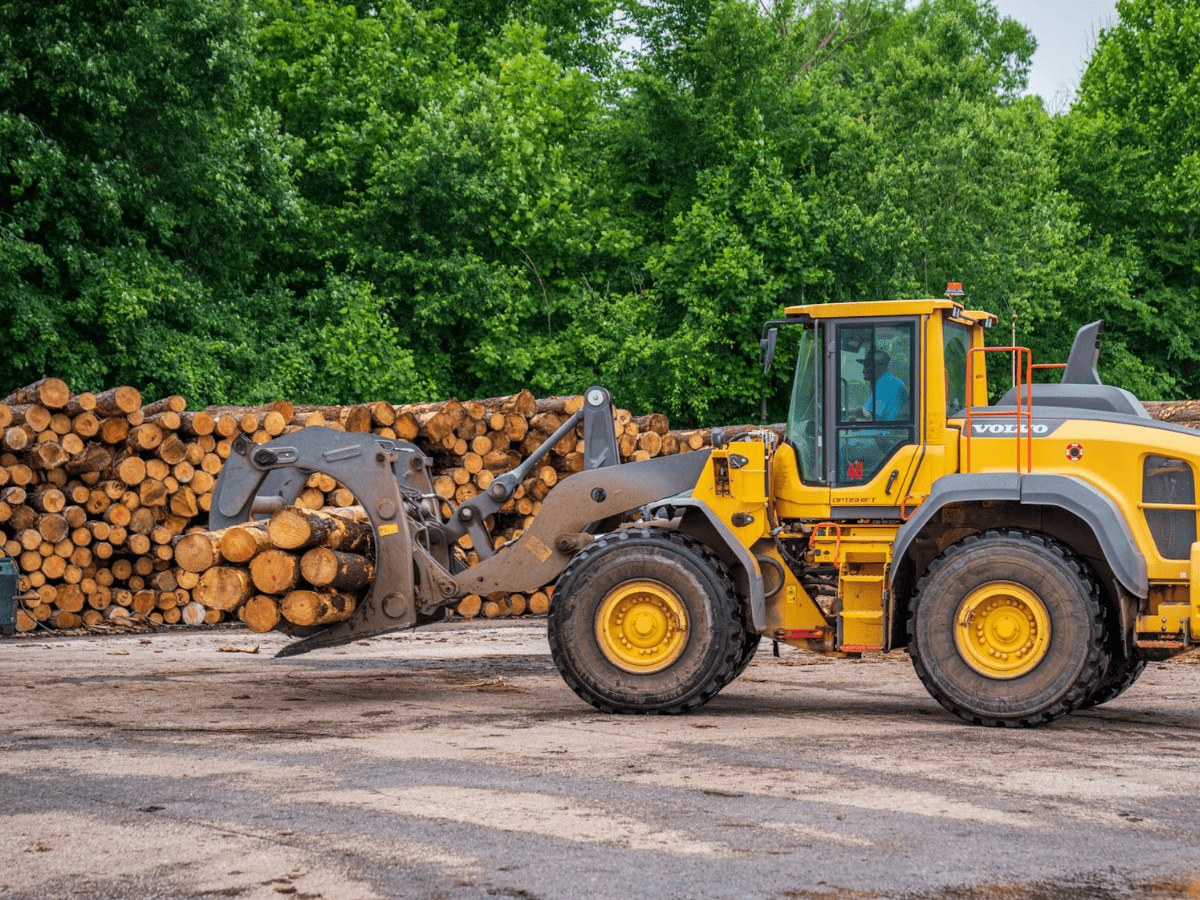

Heavy-duty heat exchanger repairs, rebuilds and manufacturing for pulping machinery, paper plants, logging machines, forestry equipment and more.

The Toughest, Heavy-Duty Heat Exchangers For The Forestry/Paper Sector

We know that fewer radiator leaks means more working, which is why we’re committed to servicing our forestry/paper customers quickly and efficiently, ensuring minimal downtime for your operations. Whether it’s a chipper, grinder, buncher, forwarder, loader or more — we specialize in welding, repairs and manufacturing for all forestry/paper heat exchangers, including radiators, cores, oil coolers, A/C condensers and more.

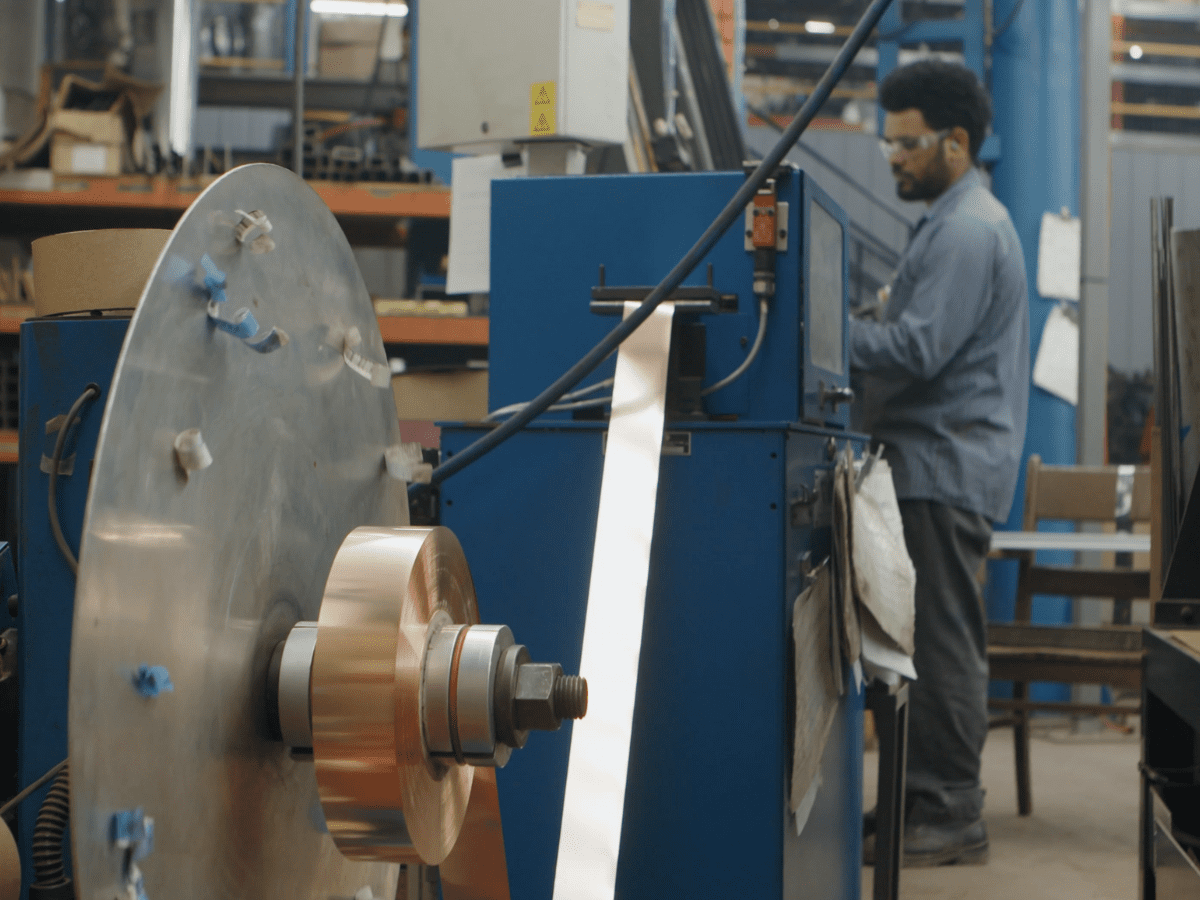

At our copper-brass and aluminum core manufacturing plants we can custom manufacture aftermarket heat exchangers for a wide range of forestry/paper OEMs, including but not limited to:

- Caterpillar

- Hino

- Hyster

- Isuzu

- Mack

- Nissan Forklift

- Toyota Forklift

We carry aftermarket Caterpillar heat exchanger parts that are built to withstand heavy-duty forestry work.

Pain Points We Solve For The Forestry/Paper Sector

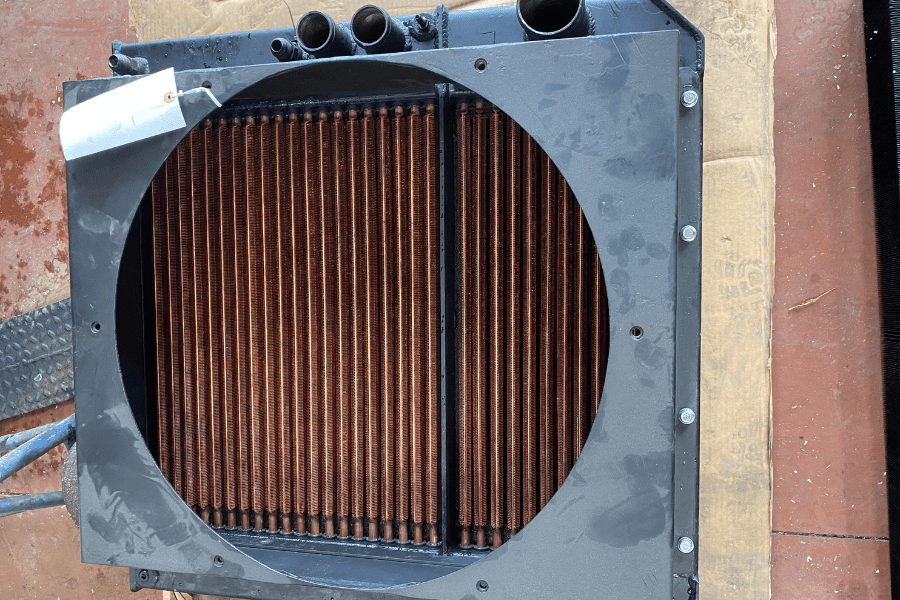

Leak-Proof Welding, Repairs & Rebuilds

We guarantee all heat exchangers leave our shop with long-lasting, high quality repairs that require less maintenance down the road.

Custom Cores Built For Your Extreme Conditions

We can custom manufacture your core from either copper-brass or aluminum with customized fins per inch, fin spacing and header styles so that your rad operates its best in any working condition.

Faster Lead Times

We can service your fleet in half the time of our competitors, reducing your overall equipment downtime by up to 70% and getting your operation back in motion.

The West End Radiators Difference

Heavier Duty Parts Than The OEM

Our raw materials are of the highest quality, resulting in our parts being up to 50% heavier duty than the OEM.

Our parts are custom engineered, analyzed and tested to ensure they can withstand the extremes of heat, cold, dirt and debris.

No Supply Chain Delays

Our in-house copper-brass and aluminum manufacturing plants allow us to minimize turnaround time by up to 70% compared to our competitors.

Customer-Focused Service

Our team is committed to ongoing, clear, transparent communication every step of the way. We answer all requests within 1 business day or less.

What our customers say

“West End Rad was the only company that was able to assist us in making us a new hydraulic oil cooling radiator that would not plug up with sawdust and dirt. We were so impressed with the way they were willing to help and find a solution, that we have since ordered another “Stay Clean” rad for another hydraulic pump skid.

Kevin Stach,

Maintenance Supervisor Lumber Company

Video Resources

Blog Resources

-

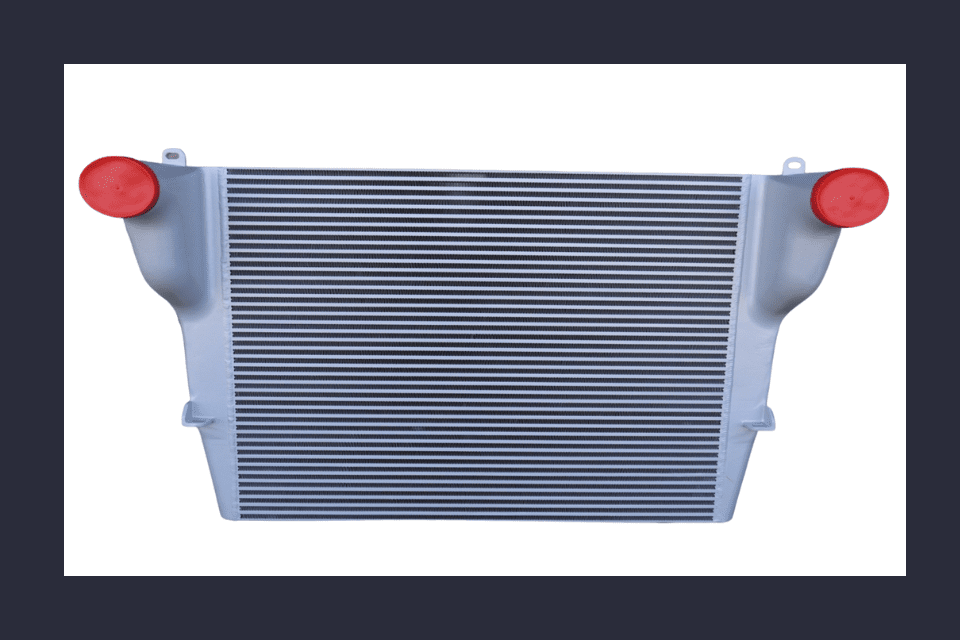

How To Maximize Fuel Mileage From Your Charge Air Cooler (CAC)

With fuel prices hitting record high around the world, we know how important it is to maximize your fuel mileage. But if your charge air cooler (CAC) is leaking, you could be losing thousands of dollars annually. This post will break down how you can maximize your fuel mileage from your CAC and what to…

-

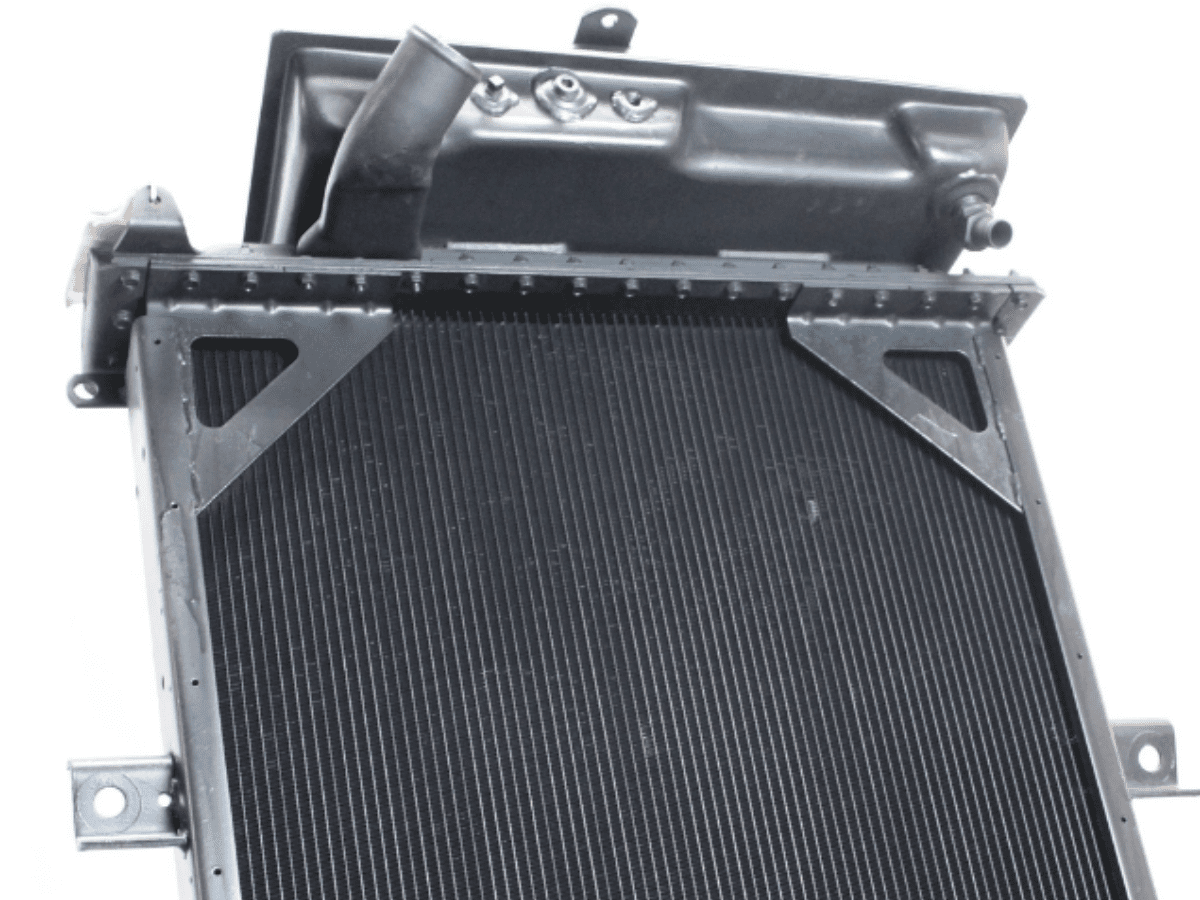

The Difference Between A WER Aluminum Core vs. The OEM

See the difference between a WER aluminum core vs. the OEM in this side-by-side comparison of the aluminum tubes, header and fins.

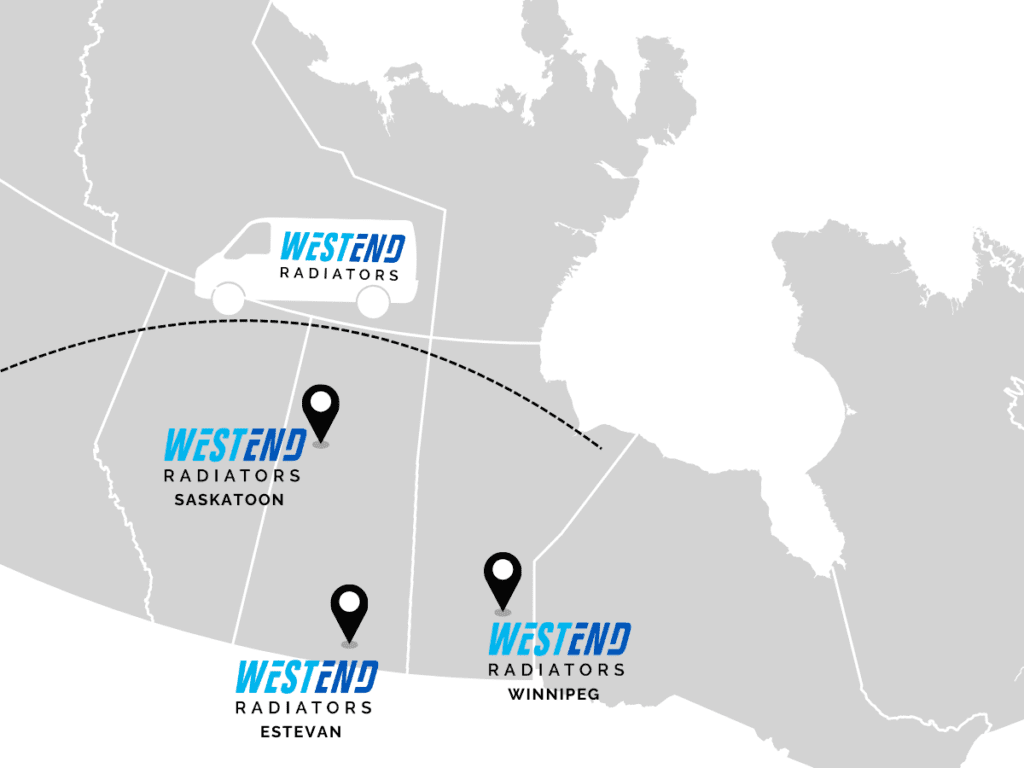

Find a location near you

Get an Estimate Today

Toll-free: 1-877-RAD-CORE (723-2673)

Winnipeg: 1-204-633-5648

Estevan: 1-306-634-2055

Saskatoon: 1-306-934-7005

Contact Us:

Please complete all the fields and our team will get back to you within 24 hours or less