Here at West End Radiators, we are committed to delivering high-quality cores backed by our industry-leading testing to meet your recore needs.

With the addition of our state-of-the-art Aluminum and Copper-Brass manufacturing facilities, we continue to invest in expanding our capabilities to serve as your trusted partner for years to come.

Our wide range of core options ensures that we can provide the best solution for your specific application, whether aluminum or copper-brass.

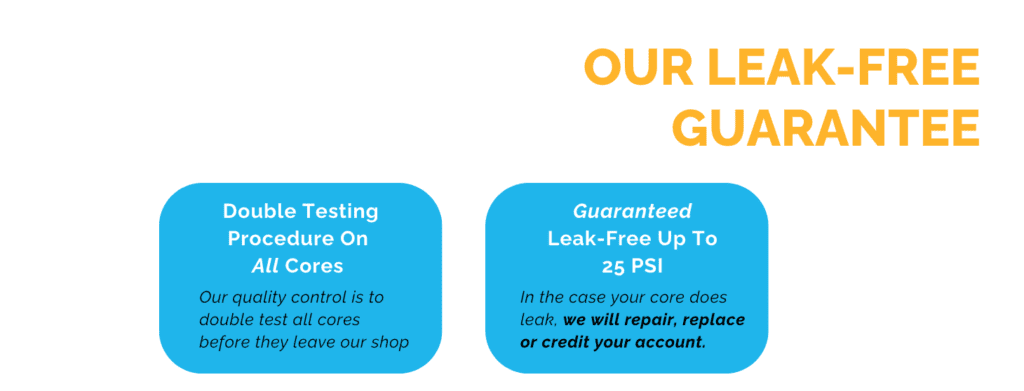

Our Unique Dual Testing Process For All Our Cores

All cores and recore work undergo our unique dual testing process, ensuring that every unit meets the highest standards of quality and performance.

This process guarantees that each core is rigorously tested for leaks and structural integrity before it leaves our facility, giving you confidence in the reliability of our products.

Whats The Difference Between Our Heavy-Duty Standardized Cores vs. A Custom Core

We offer two different styles of cores to our customers, custom or standardized, based on;

- Your timeline

- Yours/your customer’s needs

- The part you’re looking for

And while you really can’t go wrong with choosing either option, standardized or custom, there’s a few differences between the two.

Let’s walk through both so you can determine the best fit for you. Please note, sometimes our team may suggest the best option for you based on the information available and their expertise.

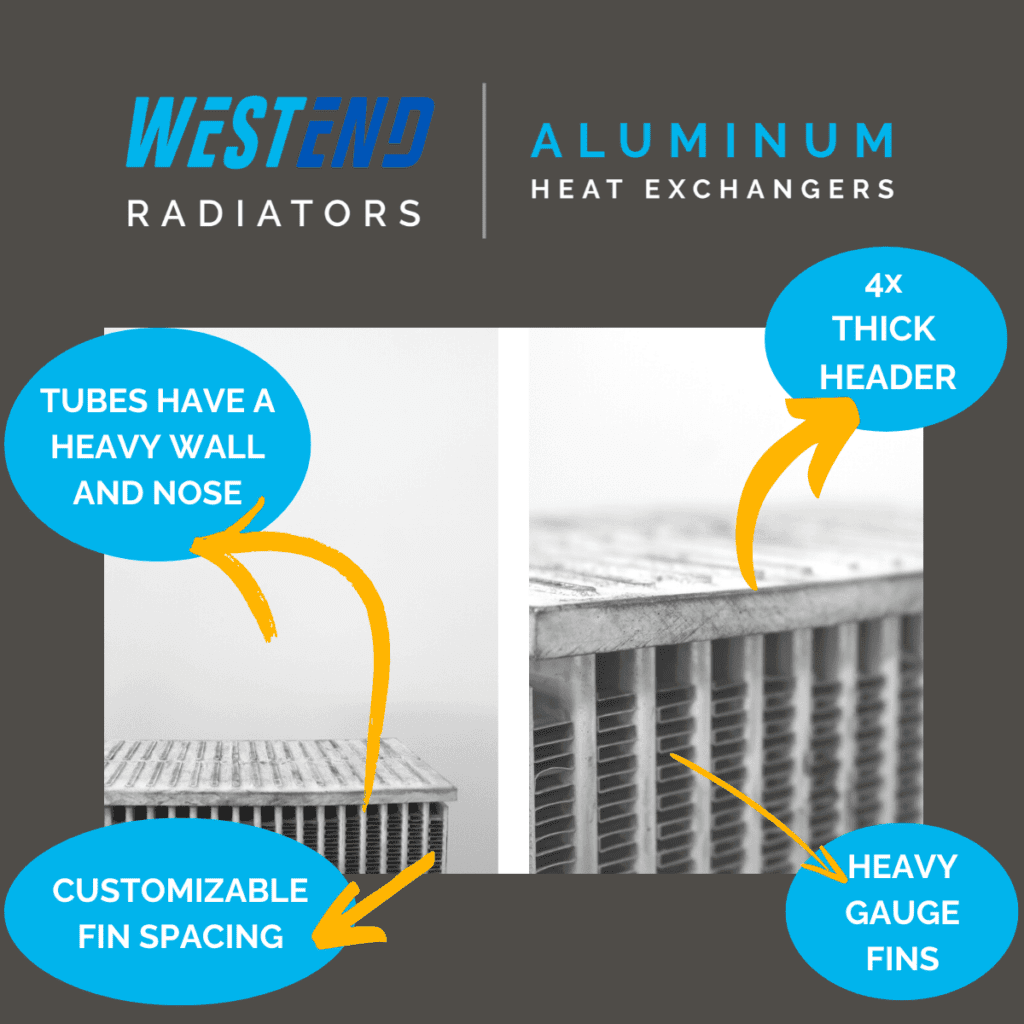

Why Choose A Heavy Duty Aluminum Custom Core

Our custom aluminum cores are ready in as little as 3-7 business days (varies based on demand)!

Additional benefits of ordering a custom aluminum core:

- Made to order based on your specifications

- Available for CAC (charge air coolers), rads and oil cooler tubes

- Available in 3 fin styles — Square Wave, Dimpled or Louvered

- Available in 4 fins per inch (FPI) spacing options — 7.5, 8, 10, and 12

- Available as a turn-up or flat header

- Comes with heavy-duty 8mm header, fins & extruded tubes

- Comes with a 1 year manufacturer warranty

Check out this video for a complete look at our entire line of Custom Aluminum Core Styles.

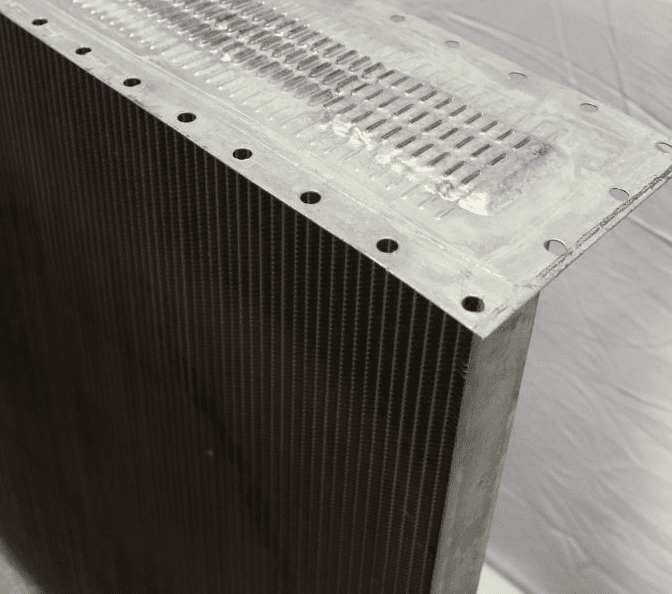

Why Choose A Heavy Duty Aluminum Standardized Core

Our standardized aluminum cores are always ready to ship to you within 2 business days!

Additional benefits of ordering a standardized aluminum core:

- High-quality, pre-manufactured core

- Always in stock, so no manufacturing delays

- Bar and plate core style

- Available in standard sizes

- Available for CAC (charge air coolers), rads and oil cooler tubes

- Made with 10.3mm Square Wave Fins

- Made with a fin spacing of 8 FPI (fins per inch)

- Comes with a 1 year manufacturer warranty

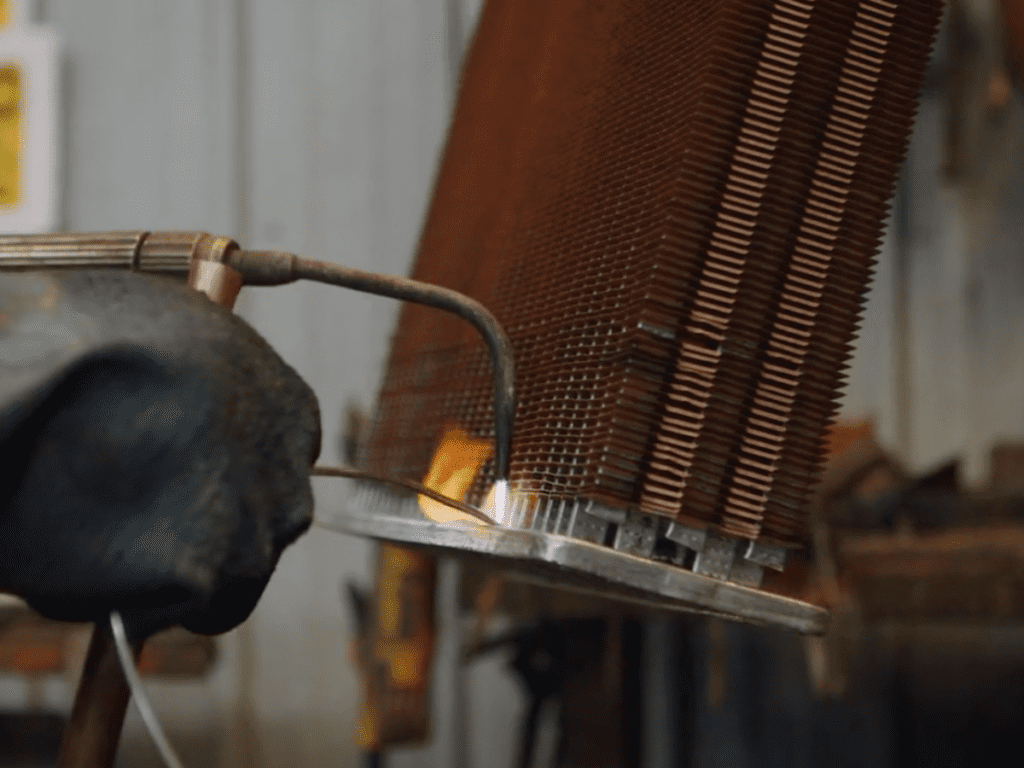

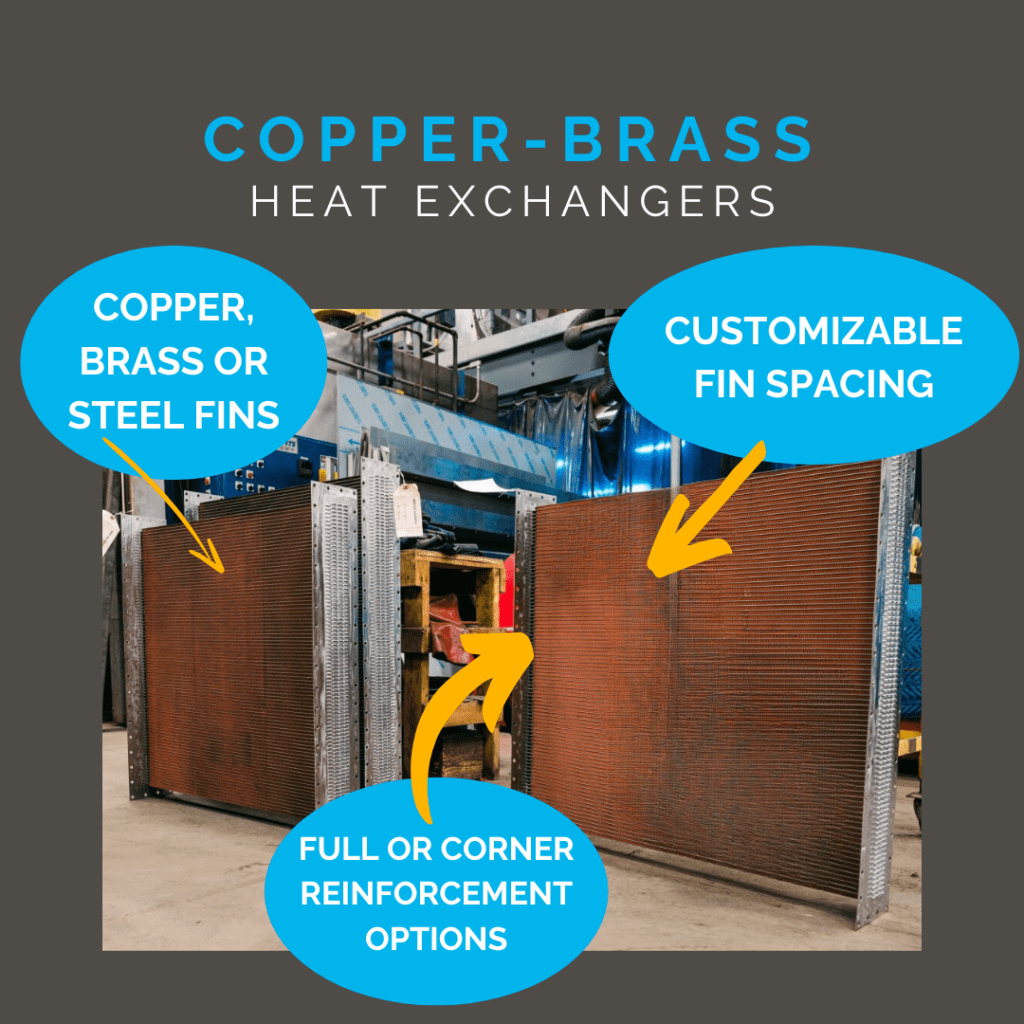

Why Choose A Heavy Duty Copper-Brass Custom Core

Our custom copper-brass cores are ready in as little as 3-7 business days (varies based on demand)!

Additional benefits of ordering a custom copper-brass core:

- Fully customizable based on your needs and specifications

- Multiple tube and fin options for optimal cooling efficiency

- Custom header configurations available

- Suitable for a wide range of heavy-duty, industrial and vintage options

- Comes with a 1 year manufacturer warranty

Check out this video for a complete look at our entire line of Custom Copper-Brass Core Styles.

Why Choose A Heavy Duty Copper-Brass Standardized Core

Our standardized copper-brass cores are ready to ship immediately upon order, and always in stock!

Additional benefits of ordering a custom copper-brass core:

- Pre-built stock cores available in our inventory

- Standardized tube and fin configurations for common applications

- Reliable and high-quality performance from our vigorous testing process

- Ideal for quick replacements with minimal downtime

- Comes with a 1 year manufacturers warranty

Find more of our copper-brass standardized parts here on our ecommerce website

3 Things That Set Our Core Engineering Apart

Our cores are engineered to deliver exceptional durability, reliability, and performance, ensuring your machinery runs at peak efficiency.

Our expert team selects the best core for your application, considering performance requirements, efficiency, and turnaround time to provide you with the best possible solution.

Here’s 3 key things that set our core engineering apart from our competitors:

1. We have an in-house team of full-time engineers and drafters working to ensure your core is customized to meet your needs.

2. We have a 3D scanner that allows us to capture all the details of any unit that needs repair or replacing and then expertly manufacture the replacement needed.

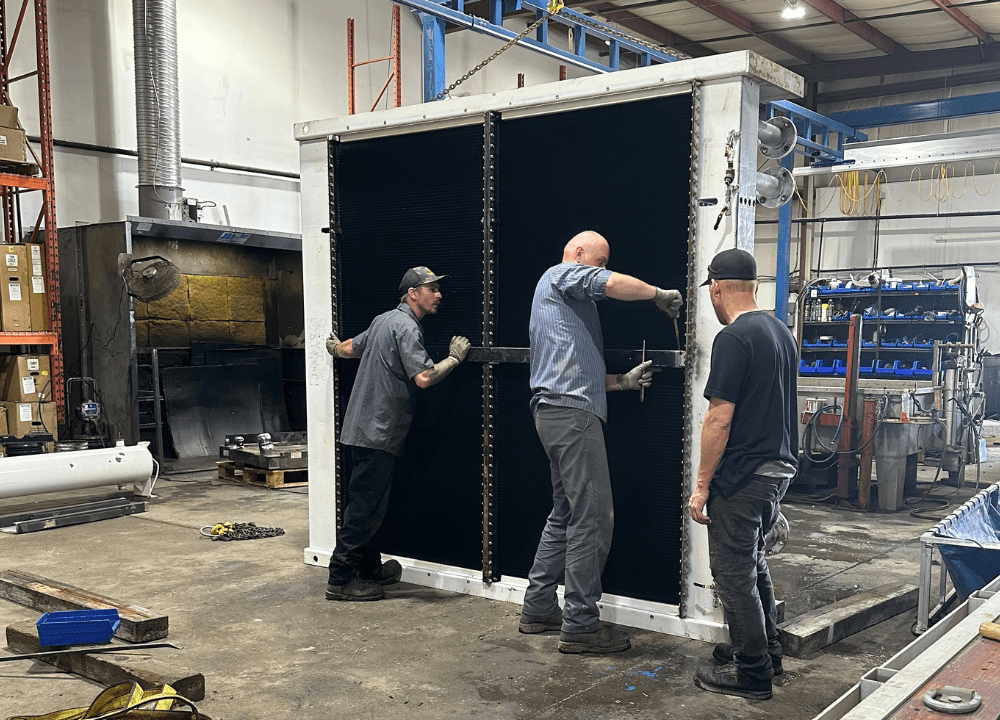

3. We have two state-of-the-art manufacturing plants with the best machinery, raw materials and technicians in the industry.

We’re Proud To Offer Canadian-Made, Heavy-Duty Heat Exchangers

Check out our video covering covering more on our in-house manufacturing capabilities.

If you have any questions, please do not hesitate to reach out.

Email: [email protected]

Toll-Free: 1-877-RAD-CORE (723-2673)

We appreciate your trust in West End Radiators and look forward to continuing to serve you!