Our new Aluminum Manufacturing Division offers our customers custom aluminum parts like never before! To really show you the difference of our aluminum heat exchangers compared to the OEM, we did a side-by-side comparison.

In this post, we analyze what makes our aluminum cores that much stronger, heavier duty and longer lasting compared to the OEM.

What To Expect With An OEM Aluminum Core

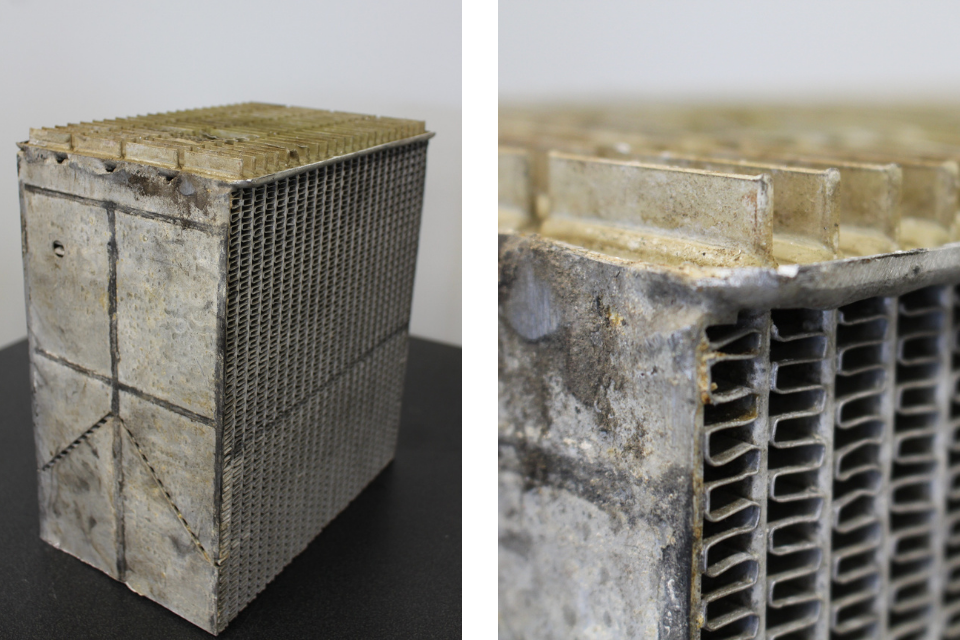

Pictured is an OEM core used in construction equipment cooling systems.

Key Disadvantages:

- Thin tube walls more prone to damage and corrosion

- Thin header plate with less support for tubes

- Lighter gauge aluminum fins

What To Expect With A West End Rad Aluminum Core

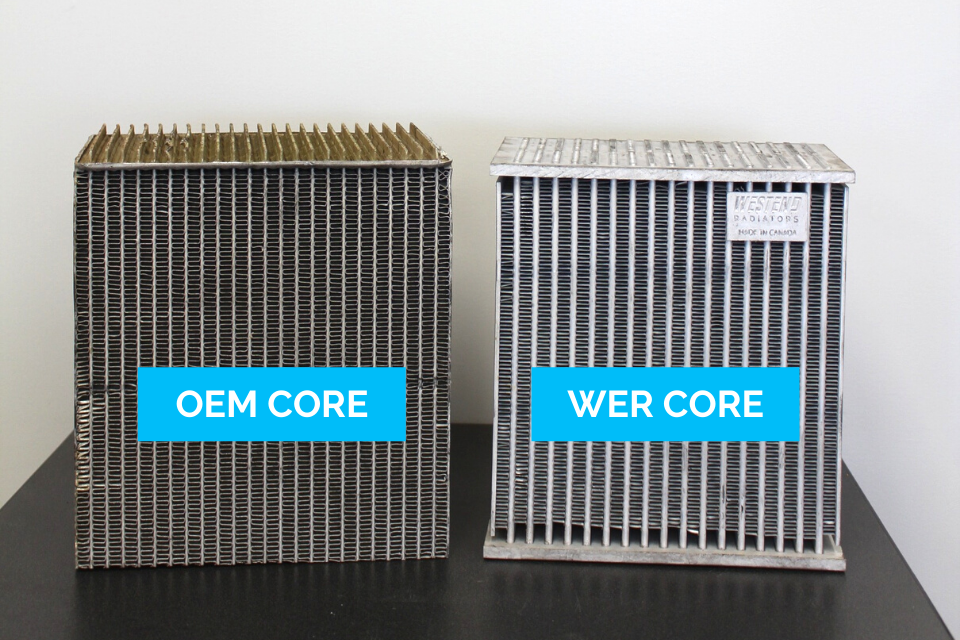

Pictured is one of our custom aluminum cores manufactured in-house in Winnipeg, Canada.

Key Advantages:

-

Thicker header, allowing for more tube support and longer service life

-

Tubes have a heavier wall and nose, which leads to less chance of damage and corrosion failure

- Fins are a heavy gauge aluminum

- Option for wider fin spacing on custom cores, which reduces debris build-up

OEM VS. West End Rad Aluminum Core

Key Differences:

- WER aluminum tubes are stronger to accommodate heavy-duty demands

- WER aluminum core headers are on average 4x the thickness of the OEM!

- WER aluminum core has heavier gauge fins with options for different fin spacing

Why Aluminum

Aluminum is a powerful resource for heat exchangers. It has extremely strong thermal properties, allowing it to conduct heat very efficiently. Aluminum is also a 100% recyclable material and 70% lighter than copper.

For more information, visit our Aluminum Heat Exchangers page where you can download our online order form to easily place your aluminum core order online.